Tyre Technical Symbols

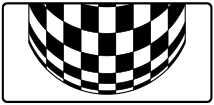

A-VBD

Stands for Advanced-Variable Belt Density technology, specifically for rear tyres. This is a jointless belt of ultra-strong Steel or Aramid strands running around the tyre's circumference. At the centre of the tread the strands are very closely spaced for maximum stability and high wear resistance. The closer you get to the edge of the tread, the further apart the strands are spaced – this broadens the tyre's footprint when you're getting your knee down.

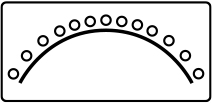

RF (Reactive Footprint)

Reactive Footprint technology marries Avon's unique variable belt density A-VBD carcass with Lifetime Profile Engineering (LPE) to produce a footprint which changes size and shape depending on the bike's lean angle for the full life of the tyre. The result is a contact patch that grows as the bike leans, giving long life when travelling in a straight line and more grip in corners.

![]()

SBC System

'Spiral and Belted Carcass'. A high level of grip puts high loads through the tyre's carcass; the SBC System features ultra-tough belts underneath the Aramid or Steel strands of A-VBD to cope with the extreme stresses.

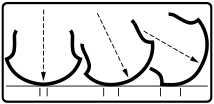

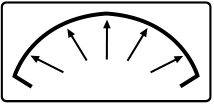

ATAC Tread Profile

Advanced Tread Arc Combination, or Tri Arc, varies the tread profile across the tyre for the ultimate in handling and stability however far over your bike is. Works in tandem with A-VBD.

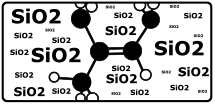

SRS-Compound (Super Rich Silica-Compound)

Compounds formulated with large amounts of silica offer enhanced grip in wet and cold conditions. This produces extra grip when the tyre is cold but also reduces excessive heat build up which can affect mileage.

Race-C

Compounds optimised for track performance.

EAF Pattern

Initials that stand for 'Enhanced Aqua Flow'. In other words, tread patterns to efficiently and rapidly clear water away from under your tyres.

ES System

Enhanced Stability System - The carcass, sidewall and tread pattern are designed to work together to reduce localised flexing within the tyre's contact patch. This increases grip and stability while at the same time reduces tyre wear.

IFG (Inverted Front Grooves)

For the front tyre, a system pioneered by Avon in the late eighties and only now being adopted by the competition, resists 'stepped-wear' and cupping to deliver smooth handling throughout the tyre's life. By significantly reducing uneven tread wear, a further advantage of the IFG configuration is improved wet braking and shorter stopping distances.

LPE (Lifetime Profile Engineering)

This works in conjunction with ATAC to produce a tyre profile and footprint which even when worn, gives consistent handling and stability for the full life of the tyre.

WCTA (Wide Custom Tread Arc)

A profile for improved manoeuverability at all speeds.

Hybrid Belt

Ultra strong steel wires of different tensions bound together to make a tape component to form a unique belt system. This belt produces exceptional high speed stability while the flexibility and natural spring properties of steel translate into superb mechanical grip. This is our most advanced belt system yet.

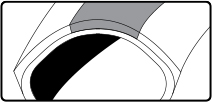

TE (Tri-compound Extrusion)

Three different rubber compounds are extruded into each tread.

Compound 1 – A durable medium compound in the centre of the tyre for improved mileage.

Compound 2 – A soft compound on the edge of the tyre for maximum grip at high lean angles.

Compound 3 – A very soft low hysteresis compound across the entire base of the tread to improve the bond between the other two compounds and the carcass.

FFG (Force Following Grooves)

Grooves that work in tandem with the forces being transmitted through the tyre at various lean angles for increased wear resistance, optimum water dispersal, reduced tyre noise and improved mileage.